製造業首屈一指的數位孿生技術解決方案

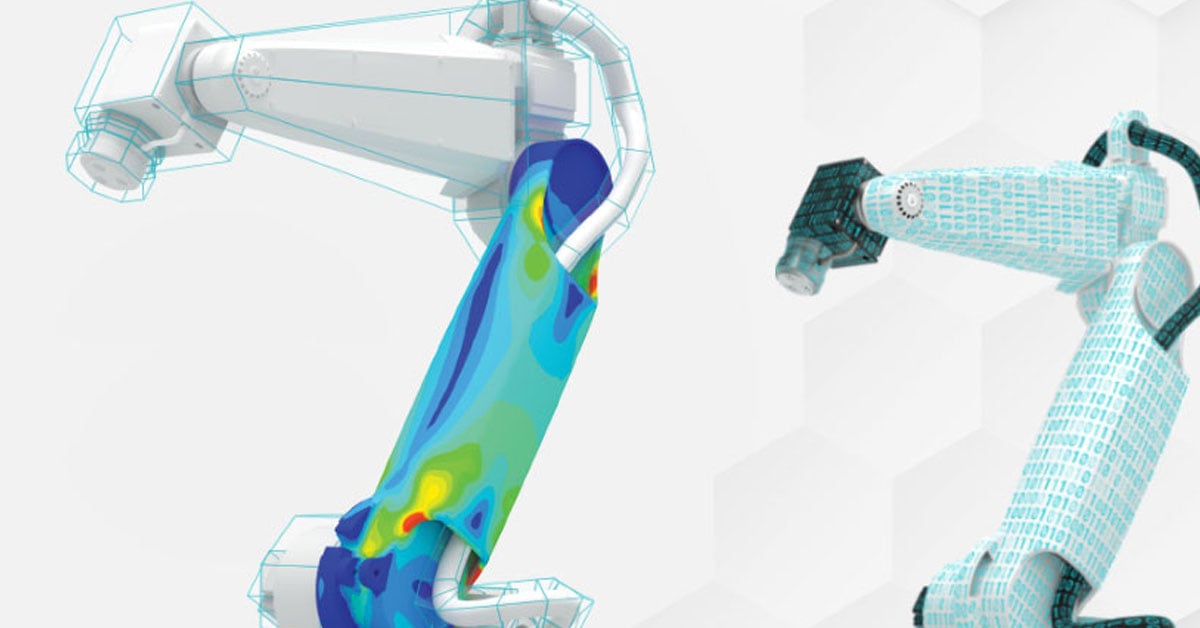

任何製造過程的目標都是完善高質量產品的設計和構造。 借助 Altair 全面的數位孿生解決方案—— 由業界最佳模擬提供支持, 人工智能 (AI)、數據分析,以及 高性能計算 (HPC) 解決方案 – 團隊和組織獲得無與倫比的端到端力量,可以釋放創新、節省時間並最大限度地減少浪費。

Altair 的數位孿生解決方案為企業提供虛擬調試、模擬技術、數位線程集成和實時資產管理。 通過利用虛擬調試和模擬功能,團隊可以優化製造 在構建系統之前,降低成本並最大限度地降低風險。 此外,數位線程在整個產品生命週期中的無縫集成可實現實時資產監控和管理,優化維護計劃並改進設備。

Altair 在製造領域的數位孿生功能還封裝了輕量化拓撲優化, 多物理場模擬, 基於模型的開發, 和更多。 正在尋找有關全球數位孿生的綜合指南? 閱讀 2022 年 Altair 數位孿生全球調查報告。

可靠的數位孿生洞察

Manufacturing Leads Digital Twin Usage

Learn how digital twin has spread in the manufacturing sector and what the future has in store for the technology, sector, and beyond. Read More

Why Digital Twin Adoption Rates are Skyrocketing

Learn why digital twin adoption is sweeping industries around the world, and how the technology improves organizations’ workflows, products, and processes. Read More

Bridging the Gaps in Digital Twin Understanding, Adoption, and Usage

In this infographic, discover how manufacturing teams can build toward alignment and eliminate internal misunderstandings, disconnects, and departmental silos. Read More

探索製造業的數位孿生技術

了解更多數位孿生中心

數位孿生行動

Digital Twin for Sustainable Energy

Improving lifetime value of a fusion powerplant using a physics-based digital twin. Assystem is an international engineering and digital services group focused on low-carbon projects that accelerate the transition to clean energy. Assystem is committed to the development of decarbonized electricity (fusion energy, renewables and electricity grids) and clean hydrogen. The Assystem team wanted to leverage the expensive design models to create a digital twin by inputting the sensor data that was livestreamed from the plant, which helps engineers understand the plant's structural integrity and further optimize inspection and maintenance schedules.

Digital Twins Boost Barista - Altair® Helps Gruppo Cimbali Speed up Innovation and Go-to Market

As a key to growth in the coffee machine industry, innovation has always been a core pillar of Gruppo Cimbali’s company philosophy. Investing in the research and development of high-performance machines is a strategic decision, and Gruppo Cimbali is proud to be recognized as one of the first companies in the sector to expand into telemetry, Internet of Things (IoT), and Wi-Fi connected machines. To continue to deliver on its innovation promise, the company now applies digital twins – utilizing Altair Activate® – to their development processes enabling it to design better products, shorten development times, and increase energy efficiency.

Digital Twin Implementation: A Strategic Tool to Improve Process/Product Capabilities in Sheet Metal Forming

Sheet Metal Forming has different and wide industrial applications (Automotive, White Goods, Aeronautic, etc....). In the metal forming industry, the simulation of processes and the resulting material behavior is of high importance. Important process parameters (e.g., material flow, temperature range, force required), as well as the resulting material characteristics (e.g., strength, residual stress, temperature resistance), can be supported using FEA to replace costly and uneconomical practical tests.

The re-use of knowledge gained from these FEA simulations in combination with data provided by different sensors is the next step towards the implementation of a Digital Twin. Its integration into the IT architecture of a digital factory is inevitable to increase the efficiency and environmental sustainability of processes and products in manufacturing. Therefore the presented project relies on Reduced Order Models in use of Machine Learning approaches as well as an IoT-based dashboard for the combined visualization of actual data and derived KPIs. As a result, the implemented solution enables significant improvement of capabilities in the considered context.

Digital Twin Platform for Optimized Product Performance | Altair

Digital twins help organizations optimize product performance, gain visibility into the in-service life of a product, know when and where to perform predictive maintenance, and how to extend a product’s remaining useful life (RUL). The Altair digital twin integration platform blends physics- and data-driven twins to support optimization throughout the products lifecycle. We take a complete, open, and flexible approach that enables your digital transformation vision on your terms.